Kaizen steps 6-10 /10

Posted by PASI JULKUNEN

This presentation is a continuation of the previous five steps, including steps 6-10. Together, they form the KAIZEN 10-step method.

6. Making a development plan

This chapter is dedicated to turning the found possible solution into the best possible solution. The group is encouraged to ride on each other's ideas or develop them further, using creative imagination and abstract thinking, visualizing how things could be if everything were perfect, without complexities and mistakes. This is the most powerful tool for finding, defining and eliminating waste. It is worth thinking about the statement of futurologist Joel Barker;

"What is impossible to do in your business today, but if it could be done, would fundamentally change the nature and quality of your business"

The development plan must be presented to the company's management if capital investments are needed, as well as any changes in the placement of equipment or the process itself. A simulation of the process must be carried out, if possible, in order to be convinced of the functionality of the new solution to solve the problem being worked on.

When planning a new layout, the design principles of an ideal layout must be kept in mind: Material handling, Operator movements, Placement of machines and equipment, Flexibility of the process for fluctuations in production volume and Principles of Standardization. All of these have numerous aspects to remember. You have to focus especially carefully on the principles of standardized work and what is behind them. I will write more about this topic later.

Before moving on to the next point, you must remember e.g.;

-Ensure that all process changes are clearly communicated to the company's management

-A list of the group's best solutions must be made, which includes actions to solve the problem at hand

-GANT chart to monitor and implement the implementation

Nobody demands perfection, but thinking about what it could be is a softer way to open people's minds to the possibility of making things better. Develop a creative atmosphere! The only way to eliminate the atmosphere of doubt about KAIZE's operation is to implement the suggestions made by the group.

7. Commissioning

Commissioning goes smoothly once proper groundwork has been done. Cooperation between different departments is often needed to implement change. If any disturbances or changes in the manufacturing process occur during the implementation phase, the materials department, the quality department and the production control department must be informed about it. Any changes made to the production process, where process machines and equipment are moved to different locations, must be informed to the company's management, and the first pieces made with a new layout must be specially marked to facilitate identification and to find possible quality deviations.

Care must be taken to avoid a situation where, when reorganizing work, the work is wrongly distributed to its creators. Work must be allocated to all team members, respecting their individual abilities.

8. Model and standardize

This step can also be part of the previous deployment step. It is important that the step is completed before the work continues in the cell subject to change.

As the title of the chapter suggests, this step refers to standardization. Since the purpose is that the solved problem never occurs again for the same reason as it was just eliminated, the new procedure must be standardized and a new standard worksheet made (Figure 1).

Figure 1 Creating a new standard worksheet

If this were not done, working in the production cell would turn into putting out fires through trial and error, leading to varying work results and resulting quality problems (Figure 2, Difference between traditional and KAIZE problem solving processes).

If this were not done, working in the production cell would turn into putting out fires through trial and error, leading to varying work results and resulting quality problems (Figure 2, Difference between traditional and KAIZEN problem solving processes).

Figure 2. Difference between traditional and Kauzen problem solving

9. Check and Fix

Since the video camera has been used effectively since the beginning of the topic, it is good to use it again to check and correct the new solution. The new Standard work form, which has been developed, may still require updates. It is particularly important to pay attention to checking the correctness of the times of the different phases of the work cycle.

The KAIZEN project tracking form, which was already partially filled in # 3 and # 4, can now be updated with the achieved results. As is the rest of the tracking sheet, including percentage improvements achieved, cost savings, implementation costs, workforce alignments, space savings, and payback period.

The identified problem must be compared with the set goals, in order to evaluate the achieved improvement. This helps to find any remaining issues that can be addressed by subsequent KAIZEN teams. If the improvement plan did not resolve the original problem, the team must return to #5, Root Cause Analysis, and proceed from there step by step again toward the final step.

Before proceeding to the next step, at least the following things must be taken into account:

- The standard worksheet must be completed

- List of unsolved problems task

-Prepare for step #10 End the presentation, by reviewing its agenda and preparing the presentation material

10. Final presentation

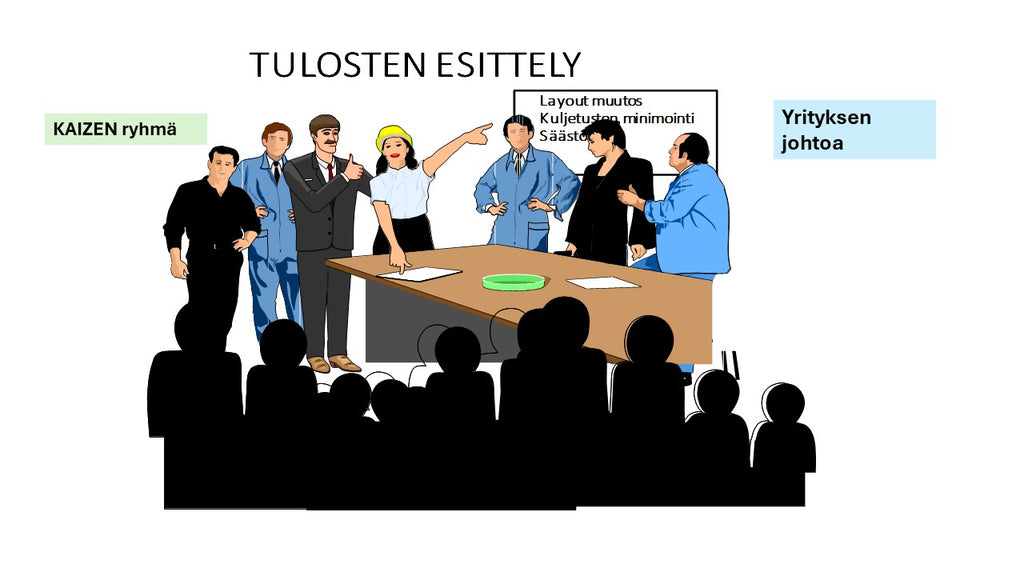

The final presentation is the most important stage of KAIZEN activities (Figure 3) . It's time to review the results achieved and give credit to team members for a job well done.

The performance should not be an artificial or elaborate event. Most of the material required in the presentation must come from the forms that have been used during the group's work, also applies to material acquired from other sources. A very effective way is to present edited video clips of what working was like before the change and what it is like after the change at the workplace.

Figure 3, The company's management listens to the employees' presentation of achievements

Among the participants in the presentation, there must be members of the management team.

The purpose of this presentation is twofold. First, it's time for the KAIZEN team to celebrate their achievements by presenting them to the management team . Secondly, by identifying the elements of success in the work done, the value of KAIZEN activity in the company increases and thus the basis of the activity in the company is strengthened.

The agenda of the presentation consists of the following areas:

- Presentation of the group members at the beginning of the event

- Summary of the presentation such as, Working time, Process description, Work subject, Work goal, KAIZEN goals

- The situation before KAIZE's activities, summarizing them for Kansilehti

- The situation after KAIZE's activities, summing them up for Kansilehti

- List of outstanding issues

- List of achievements in the project, cost savings, quality improvements, investments, payback period

- Gemba, i.e. a visit to the work cell

- Question and answer phase

The length of the presentation is about 20 minutes

In my next article, I will discuss an important aspect of KAIZEN activities, professional initiative activities. It is very different from what is generally meant by initiative activity, e.g. in terms of content of initiatives, goal setting and cost management.

Pentti Enlund

MexLink Oy

English

English Finnish

Finnish Swedish

Swedish German

German